Unraveling the Mystery of Supply Chain Management

Supply chain management is a complex and intricate process that involves the coordination of various activities to ensure the smooth flow of goods and services from the point of origin to the point of consumption. For many people, the world of supply chain management can seem like a mysterious and daunting place, filled with jargon and technical terms that can be difficult to understand.

But fear not! In this article, we will demystify the world of supply chain management and get back to basics to help you understand the key concepts and principles that underpin this crucial business function.

At its core, supply chain management is all about ensuring that the right products are in the right place at the right time, and at the right cost. It involves a series of interconnected activities, from sourcing raw materials to manufacturing products, to distributing them to customers. By effectively managing these activities, companies can minimize costs, improve efficiency, and enhance customer satisfaction.

One of the key components of supply chain management is demand forecasting. This involves predicting how much of a product will be needed in the future, so that companies can plan their production and distribution activities accordingly. By accurately forecasting demand, companies can avoid stockouts and overstock situations, which can result in lost sales and unnecessary costs.

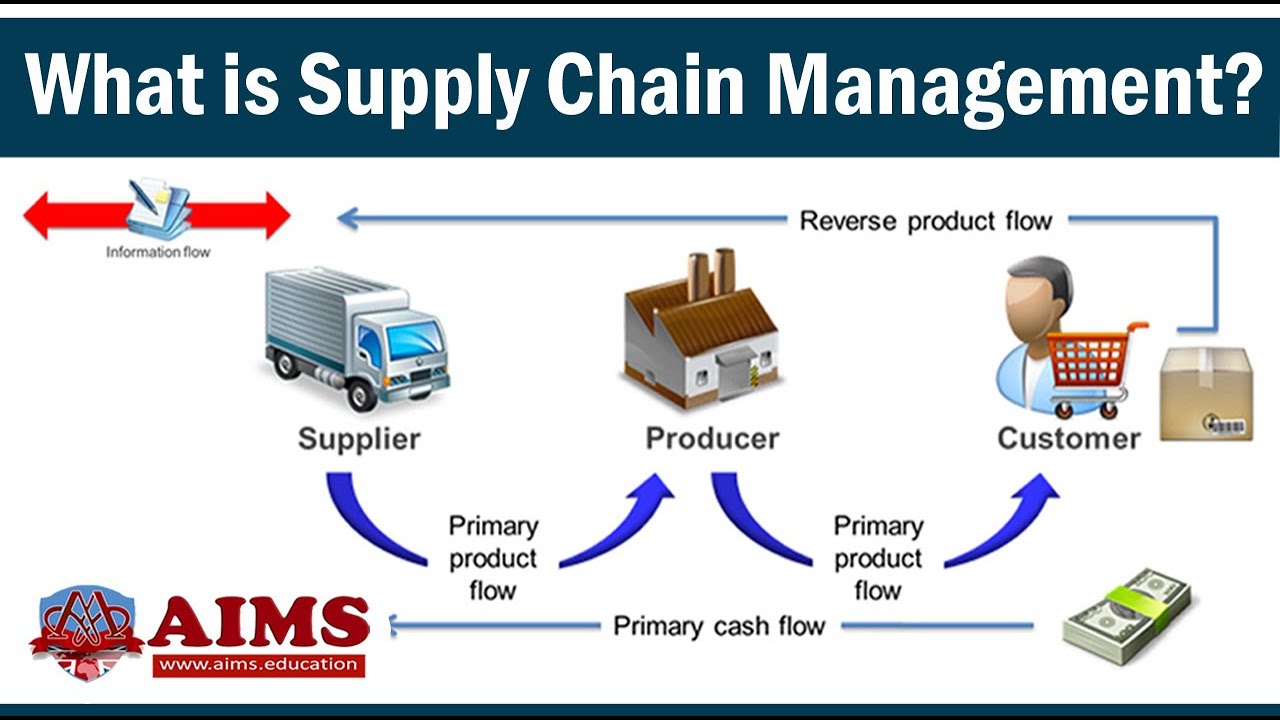

Image Source: ytimg.com

Another important aspect of supply chain management is inventory management. This involves the control and monitoring of inventory levels to ensure that companies have enough stock on hand to meet customer demand, without holding excess inventory that ties up capital. By implementing effective inventory management practices, companies can reduce costs, improve cash flow, and increase overall efficiency.

In addition to demand forecasting and inventory management, supply chain management also involves logistics and transportation. This includes the planning, implementation, and control of the movement of goods from suppliers to manufacturers, and from manufacturers to customers. By optimizing logistics and transportation processes, companies can reduce lead times, minimize shipping costs, and improve overall customer satisfaction.

One of the key principles of supply chain management is collaboration. In today’s globalized world, supply chains are becoming increasingly complex, with multiple suppliers, manufacturers, and distributors involved in the process. By fostering collaboration and communication between all parties, companies can streamline their supply chain operations, reduce risks, and enhance overall performance.

Technology also plays a crucial role in supply chain management. By implementing advanced software systems and tools, companies can automate many of the routine tasks involved in supply chain management, such as inventory tracking, order processing, and demand forecasting. This not only helps to improve efficiency and accuracy but also allows companies to respond more quickly to changing market conditions.

In conclusion, while supply chain management may seem like a mysterious and complex field, at its core, it is all about ensuring that products are delivered to customers in a timely and cost-effective manner. By understanding the key principles and concepts that underpin supply chain management, companies can optimize their operations, reduce costs, and improve customer satisfaction. So let’s demystify the world of supply chain management and get back to basics to drive success in today’s competitive business environment.

Let’s Get Back to Basics with SCM Essentials

Supply chain management (SCM) is a complex and dynamic process that involves the flow of goods, information, and finances from the raw material stage to the final consumer. In today’s fast-paced and globalized world, the importance of SCM cannot be overstated. It is the backbone of any successful business, ensuring that products are delivered to customers in a timely, cost-effective, and efficient manner. In this article, we will delve into the essentials of SCM and demystify this crucial aspect of business operations.

At its core, SCM involves the coordination and integration of various activities such as procurement, production, inventory management, transportation, and distribution. By optimizing these processes, businesses can minimize costs, improve customer satisfaction, and gain a competitive edge in the market. The key to effective SCM lies in understanding and mastering the fundamentals of the supply chain.

One of the essential components of SCM is procurement, which involves sourcing raw materials or goods from suppliers. By establishing strong relationships with reliable suppliers, businesses can ensure a steady supply of high-quality materials at competitive prices. This not only reduces costs but also minimizes the risk of disruptions in the supply chain.

Production is another critical aspect of SCM, where goods are manufactured or assembled according to demand. By forecasting demand accurately and optimizing production processes, businesses can avoid overproduction or stockouts, leading to lower inventory costs and improved efficiency. Additionally, implementing lean manufacturing principles can help streamline production and eliminate waste, further enhancing the overall supply chain performance.

Inventory management is another crucial element of SCM, as it involves controlling and optimizing the levels of inventory to meet customer demand. By implementing effective inventory control systems, businesses can reduce carrying costs, prevent stockouts, and improve order fulfillment rates. Just-in-time (JIT) inventory management is a popular strategy that aims to minimize inventory levels while ensuring timely delivery of products to customers.

Transportation plays a vital role in SCM, as it involves the movement of goods from suppliers to manufacturers and from manufacturers to customers. By selecting the right transportation modes and carriers, businesses can minimize lead times, reduce shipping costs, and enhance overall supply chain efficiency. Additionally, technologies such as route optimization software and GPS tracking systems can help streamline transportation operations and improve delivery performance.

Distribution is the final stage of the supply chain, where finished goods are delivered to customers through various channels such as retailers, wholesalers, or e-commerce platforms. By optimizing distribution networks and partnering with reliable logistics providers, businesses can ensure timely and accurate delivery of products to customers. Efficient distribution processes can lead to higher customer satisfaction, repeat purchases, and ultimately, increased profitability.

In conclusion, supply chain management is a critical component of business success, and mastering the essentials of SCM is essential for any organization looking to thrive in today’s competitive marketplace. By focusing on procurement, production, inventory management, transportation, and distribution, businesses can optimize their supply chain processes, reduce costs, and improve overall efficiency. So let’s get back to basics with SCM essentials and demystify the complexities of supply chain management for a brighter and more prosperous future.

Understanding the Basics of Supply Chain Management